Making Optimal Use of

Your Resources

Efficient Follow-up, Without Paper

Paper becomes obsolete reducing the risk of errors and makes follow-up more efficient. Operators are shown the data relevant to them directly on a screen. In addition, a central database makes it easier to evaluate the status of production and to draw up an optimal schedule.

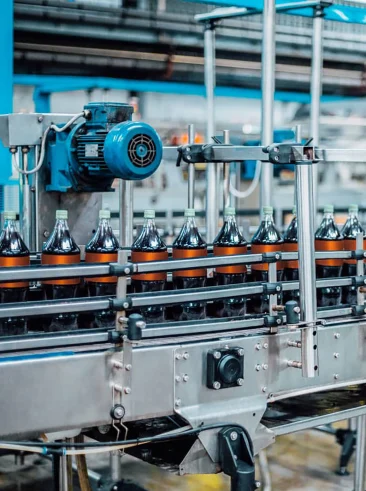

Real-time Traceability and Analysis

Our systems register and analyse all steps in your production and logistics processes providing all the information you need to make the right decision at all times. With real-time information, you will be able to intervene quickly as production issues and bottlenecks come to light. In addition, the data history gives you insight into underlying causes and possible points for improvement.

Visibility of Supply Chain Performance

Optimally manage your production and logistics, from gate-to-gate. Efficiently control and monitor your production process, warehouse and employees in real-time.

Flexibility, Security and Scalability

With our SaaS deployment option, you can rest easy knowing that you’re on Aptean Cloud. With 99.9% uptime and disaster protection, your data is readily available and backed up. Being in the cloud, you will have the flexibility to securely access your data from anywhere and ensure your system is up-to-date—gone are days of time-consuming upgrades.

Real-time Monitoring of Your Production Performance, Machine Status and Quality

One of the core tasks of Aptean MES is the real-time supervision and management of the production performance. All relevant production data and information is captured, processed and visualised via dashboards.

In addition to managing the performance of the production process, the analysis of the performance losses is also a real added value. Aptean MES offers handy Pareto analysis, a function that allows you to highlight and address production issues causing the highest impact.

Aptean MES gives you unambiguous and correct information about KPI’s such as yield, rework, cycle times, OEE, causes of machine stoppages, material consumption and efficiency of operators. This way, you can benchmark your performance against reference figures at any time.

Advanced Planning and Scheduling

With the planning module of Aptean MES you create an efficient production planning manually or automatically, taking into account the availability of machines, resources and people.

Based on algorithms, the automatic scheduler will generate a planning proposal that is most in line with the predefined KPIs. Once the optimal planning has been reached, operations are released to the shop floor and further monitored in real time in the planning board.

In addition, you can experience these operational benefits of Aptean MES:

Optimisation of your productivity

Speed and flexibility towards costumers

Quality assurance and improvement

Efficiency of machines and people

Use of energy and utilities

Reduction of WIP, stock, waste, scrap and rework

100% product safety and traceability

Paperless production: fewer errors, higher efficiency

Power of Work Force Management

If your company produces and/or takes care of its own logistics operations, integration of these domains with your workforce production management is crucial providing you with numerous advantages:

Correct logging and validation of working hours

Optimising personnel and capacity planning in terms of anticipated work

True allocation of working hours to production orders and logistics tasks

Register exact times on production orders so that you can realise an accurate production report and a correct subsequent calculation. By comparing standard times for specific jobs, you can also check unsubstantiated deviations and adjust them where necessary.

Our software solution forms a comprehensive operational management of personnel, production and logistics: the ultimate step in the pursuit of operational excellence.

Related Content

Ready to start transforming your business?

We’ve got the specialised MES solution you need to conquer your industry challenges.