Featured in this post

EAM vs ERP: Competitors or Partners?

EAM vs ERP: Competitors or Partners?

27 Aug 2024

Aptean Staff Writer

If you’re planning a digital transformation, it’s easy to become overwhelmed with the “alphabet soup” of potential software systems available to optimise your operation. ERP, PLM, EAM, WMS, OEE, TMS—the options seem endless, but understanding their specific roles and advantages is crucial. Even just remembering what all those three-letter initialisms stand for is no small task.

You can read an overview of each of these manufacturing software systems in our introductory blog, but here we’re going to take a deep dive into two commonly confused systems: enterprise asset management (EAM) and enterprise resource planning (ERP).

Both offer unique benefits and functionalities to streamline your business operations and understanding them is essential for optimising your organisation's performance.

To get you started, we’ll break down the core differences and similarities between EAM and ERP systems. We’ll also explore the benefits each offers alone and discuss how they can work together to enhance the efficiency of your assets as well as business operations.

So, whether you're looking to implement one or both solutions, this guide will provide valuable insights to help you make an informed decision, leverage these systems to their full potential and maximise their combined power for operational excellence.

EAM and ERP: The Basics

It's essential to start with clear definitions of ERP and EAM to understand fully how they can benefit your organisation. This foundational knowledge will help you grasp their unique functionalities and how they can be applied to enhance your business operations.

What Is Enterprise Asset Management (EAM) Software?

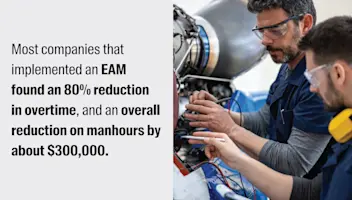

EAM software manages the entire lifecycle of physical assets within your organisation. An EAM system optimises the performance, maintenance and utilisation of your assets such as equipment, facilities and vehicles so that they run smoothly and function optimally for as long as possible. This enables you to maximise manufacturing uptime, meet customer demands and increase your profitability efficiently.

What Does an EAM System Do?

By managing each stage of an asset's lifecycle, from acquisition to disposal, an EAM system helps your organisation optimise asset utilisation and return on investment (ROI). It tracks performance metrics in real time, enabling proactive maintenance and reducing downtime. By analysing asset conditions in this way, EAM software helps extend asset life, prevent costly breakdowns and ensure regulatory compliance through automated inspection and incident tracking.

EAM systems also focus on cost optimisation by monitoring the total cost of ownership (TCO) and helping you implement predictive maintenance strategies. These features allow organisations to schedule maintenance based on real-time data, ensuring interventions occur only when necessary, thereby reducing unplanned downtime and maximising asset value. It helps to develop proactive maintenance strategies that enable condition-based maintenance scheduling.

Which Industries Commonly Use EAM?

EAM solutions are valuable for any asset-intensive industry where the proper functioning and maintenance of physical assets are critical to operations. Industries that benefit most from EAM software include:

Manufacturing

Energy and utilities

Transportation and logistics

Healthcare and pharmaceuticals

Food and beverages

What Is Enterprise Resource Planning (ERP) Software?

An ERP system forms a centralised and standardised hub for operational data that streamlines core business functions like procurement, production, inventory management, accounting and sales. By integrating these processes and providing real-time data visibility, an enterprise resource planning system improves efficiency, accuracy and decision-making across your organisation. Implementing an industry-specific ERP system provides additional value with specialised features for your unique market challenges—boosting ROI and driving growth.

What Does an ERP System Do?

By standardising data management and streamlining key processes, ERP ensures consistent operations and automates repetitive tasks, reducing errors and freeing up time for strategic activities. With real-time inventory management and accurate demand forecasting features, ERP software enables effective production planning and scheduling to avoid costly shortages and surpluses. Other key features include supply chain management, quality control and reporting allowing you to drive efficiency, improve productivity and enhance customer satisfaction.

Industry-specific ERP solutions offer specialised features tailored to different sectors. For example, an advanced food and beverage ERP tracks expiration dates and enhances allergen management. Meanwhile, the best distribution ERP should include chargeback handling and integrated electronic data interchange (EDI), and an apparel ERP with an embedded vendor management portal is preferred.

Which Industries Commonly Use ERP?

By integrating core business functions into a unified platform, an ERP system offers significant benefits across various industries.

ERP systems are versatile, so can provide value to a wide range of businesses in many sectors, including:

EAM vs ERP: What’s the Difference?

Understanding the distinct features of enterprise asset management and enterprise resource planning systems is crucial when choosing one for your business. Each system serves unique purposes and offers different functionalities tailored to your specific business needs. By comparing the key facts about EAM and ERP, you can determine which system best aligns with your organisational goals and operational requirements. Here’s a closer look at how one system differs from the other.

EAM vs ERP: What’s the Difference?

Overlapping Capabilities

While EAM and ERP systems have distinct primary functions, there are areas where their capabilities intersect:

Inventory Management: Both systems offer inventory tracking, though EAM focuses on maintenance parts while ERP covers broader inventory management for production materials.

Procurement: EAM systems may include basic procurement features for maintenance-related items, while ERP systems offer more comprehensive procurement capabilities.

Reporting and Analytics: Both systems provide reporting tools, with EAM focusing on asset performance and ERP offering advanced business analytics for various functions.

Can EAM and ERP Work Together?

Simply put—yes. Considering these systems shouldn’t be an either-or decision because, to answer our titular question, they make perfect partners rather than competitors. By combining the strengths of both ERP and EAM, your organisation can gain better financial insights, avoid duplicate tasks, make assets more profitable and automate crucial processes.

While most businesses will choose to implement ERP software first as the foundational platform to build their digital transformation upon, ensuring EAM is part of your roadmap can unlock big benefits. When properly integrated, ERP and EAM complement each other, forming a powerful partnership that enhances the overall performance of your business—reducing costs, improving decision-making and driving profitability. For example, combining ERP and EAM in discrete manufacturing creates a cohesive system that optimises resource use, boosts asset performance and drives operational success.

The Benefits of Integrating EAM and ERP

Better Decision-Making

Integrating EAM and ERP systems enhances decision-making capabilities by providing a holistic view of asset and business operations. This comprehensive end-to-end insight allows managers to make data-driven decisions quickly and effectively to ensure your production is always on track. With accurate, real-time data on available inventory, current and projected demand, asset performance, and maintenance schedules, decision-makers can identify trends, predict issues before they arise, and implement strategies that align with your company's long-term goals. This results in more proactive management of daily production schedules, on-time order fulfilment and enhanced strategic planning—ultimately boosting the overall profitability of your organisation.

Enhanced Efficiency

Combining the automations of ERP software with the digital asset tracking of EAM systems leads to significant improvements in operational efficiency. By enabling seamless data flow, the integrated solution eliminates the need for manual data entry and reduces the risk of errors. This streamlined approach allows your employees to focus on more value-added tasks, ultimately boosting productivity across your organisation.

Cost Savings

One of the most compelling benefits of integrating EAM and ERP systems is the potential for substantial cost savings. The combined power of these systems allows your company to optimise resource allocation by providing robust forecasting, stock accuracy and a comprehensive view of asset utilisation and maintenance needs. This insight helps reduce unnecessary production delays, stoppages, material/ingredient waste, maintenance costs and unexpected breakdowns—so you’re always getting the most out of all of your resources. Additionally, the integration enables more accurate financial planning and budgeting by aligning asset management strategies with overall business objectives. As a result, your company can make more informed investment decisions and improve return on assets (ROA).

Scalability and Flexibility

Together EAM and ERP systems provide significant scalability and flexibility. As your business grows, these combined systems can adapt to increasing data volumes and more complex operations without a complete overhaul. Advanced systems also offer customisable configurations that align with your specific business or industry needs, allowing for quick adjustments to market changes and process improvements. This ensures that your enterprise management solutions evolve with your business, maintaining your competitive edge and effectively addressing emerging challenges.

Improved Compliance and Reporting

Integrated EAM and ERP systems offer a holistic view of asset performance and business operations, which is crucial for ensuring compliance with industry regulations and improving reporting capabilities. The combined and standardised data from both systems provides a unified view of your operation, enabling more accurate and comprehensive reporting on asset health, financial performance and regulatory compliance. This integrated approach simplifies audit processes and helps your organisation quickly identify and address potential compliance issues.

Maximise Your Profit With Aptean's EAM and ERP Solutions

With so many software systems available, all promising to “revolutionise” your business, it can be difficult to understand where every piece of the puzzle fits and exactly what your business needs. Hopefully, we’ve highlighted here that some solutions are complementary and can actually provide additional benefits when combined, rather than competing.

As we mentioned, ERP is most commonly deployed first to integrate various business processes—such as supply chain management, finance and inventory management—into a unified and standardised system, enhancing overall efficiency and decision-making. Then an EAM system is integrated into the tech stack to focus on extending the life and efficiency of physical assets, ensuring they are well-maintained and operating at peak performance. Once these EAM and ERP systems are combined, the highly integrated solution aligns asset management with broader business processes and improves efficiency and accuracy.

At Aptean, we understand the unique needs of your business and specialise in providing complementary systems to solve all of your operational challenges and create a seamless flow of information. Our ERP and EAM solutions deliver a cohesive approach that helps reduce redundant processes, improves data accuracy and enhances decision-making across the board, relieving you of unnecessary burdens.

What’s more, we provide a range of additional systems to drive your full digital transformation journey—from product lifecycle management (PLM) software to transportation management systems (TMS) This allows you to leverage the benefits of using one vendor for all your software needs, access the expert guidance and support of our in-house teams, and pace your software roadmap to suit your business requirements.

Our experts are here to guide you in selecting and implementing the right solution for your needs—get in touch today to schedule your personalised demo or find out more about our ERP and EAM systems.

Related Content

Ready to start transforming your business?

We’ve got the specialised EAM solutions you need to conquer your industry challenges.