Fast-Moving Consumer Trends Can Cause Electronics Manufacturers To Short Circuit

Fast-Moving Consumer Trends Can Cause Electronics Manufacturers To Short Circuit

Fast-Moving Consumer Trends Can Cause Electronics Manufacturers To Short Circuit

29 Jun 2021

Jim Tuttle

Manufacturers may build products to last, but that doesn’t mean people or companies will keep them until they wear out. There’s a constant pressure to embrace new trends and own the latest version of every gadget; to be faster, smarter, and more capable through the use of technology.

For electronics manufacturers, this is putting major pressure on production lines. Reports have shown that the average lifespan of products, such as smartphones, washing machines and televisions, are 2.3 years shorter than designed, as households trade-in existing tech for something more up-to-date. And many businesses are also replacing electronic investments before the end of their life, to ensure they are running quicker than the competition.

The ecological impact of these frequent changes is a conversation in itself; only 20% of global electronic waste is recycled. But for manufacturers, the problem starts at the beginning of the lifecycle. So, how can you keep pace with increasing demand for electronics?

Understand How Demand Is Evolving

To run at speed, electrical equipment manufacturers need every element of your business operation to function smoothly. And there are key areas to optimize to support rapid product innovations.

The first of these is forecasting and demand planning. How well do you understand your customer base? Are you keeping pace with their requirements, and anticipating where their business is heading next?

In the fast-paced electronics manufacturing environment, knowledge is power. Real-time data insight will enable your organization to see where demand is coming from and how it’s evolving, to make strategic decisions that support business growth.

The electronics industry is under constant pressure to engage and excite end buyers with new digital features. The closer you can work with product developers to understand what these features are and create accurate, dependable plans, the faster you can move. And the simplest way to extract the data insights needed to plan ahead is by using specialist industrial manufacturing enterprise resource planning (ERP) software.

Manage Complex Production Processes

The next area that electronics manufacturers should look to optimize is scheduling and production. When you can see demand patterns developing, how do you plan ahead to get new innovations built and distributed as quickly as possible?

One of the reasons that demand planning and forecasting is so critical in electronics manufacturing is the complexity of devices now being produced. The number of ‘smart’ products continues to increase year over year; the smart home market is the current biggest growth area, driven by appetite for wireless communication technologies. In fact, the smart home industry is predicted to reach $135.3 billion global value by 2025.

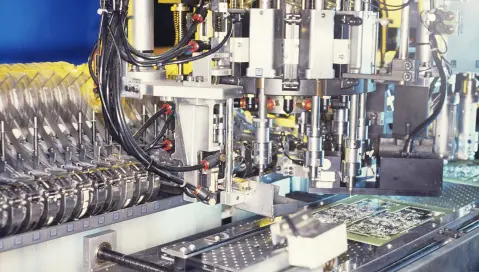

As the technical proficiency of products increases and competition pushes companies to go smaller and sleeker in their design, producing electronic goods becomes a much greater challenge. Manufacturers are dealing with complex assembly processes involving multiple small parts, requiring specialist micro-production techniques and processes to create.

Ideally, electronics manufacturers should be focusing on detail and accuracy. But all too often, other factors impact the production line—particularly material supplies. Industrial manufacturing ERP software enables you to create an accurate bill of materials for every job, and correlate that information with real-time inventory availability, so that a lack of parts never stops production.

Crucially, it also enables your workforce to see the delivery schedules for any components that are missing, and to look for alternatives as necessary. And with greater confidence in your supply chain capabilities, you’re less likely to overstock, so component catalogues can evolve in line with customer demand.

Produce High Quantity Without Compromising on Quality

Getting products to market quickly is vital when consumer demand is shortening product lifecycles. But this cannot be at the expense of quality, or it could have a negative effect on your reputation.

To maximize efficiency while maintaining standards, two key elements need to be in place. The first is process accuracy; the more you can automate through ERP software, the faster and more efficiently your production line will run. Using technology to drive assembly ensures a level of standardization and consistency that isn’t achievable at speed through manual workmanship.

The second area your organization needs to optimize is compliance and quality control checks. If certain requirements or standards of work are built-in to the production line, you can feel confident that every item you ship will live up the end buyer’s expectations. And minimizing product returns or recalls is pivotal to maximizing your bottom line.

Scale Your Operations Without Short Circuiting

Strong consumer appetite is a good thing for the electronics industry; the faster the market moves, the quicker and more frequently products are likely to sell. The challenge that electrical equipment manufacturers have is being able to keep pace with business growth opportunities, without compromising on quality or profitability.

Industrial manufacturing ERP software empowers you to optimize the parts of your business that are most likely to short circuit when running at speed. So, you can scale-up production while maintaining your reputation, and you become a trusted partner for companies that want to capitalize on emerging consumer electronics trends.

Aptean industrial manufacturing solutions enhance visibility, delivery and performance for computer, electronics and electrical equipment manufacturers. Get in touch with our team of industrial manufacturing experts to book a demo.

Related Blogs

Start transforming your business today

If you’re ready to take your discrete and industrial manufacturing business to the next level, we’d love to help.