Destacado en este post

10 Benefits of Shop Floor Management Software

10 Benefits of Shop Floor Management Software

20 Jul 2023

Aptean Staff Writer

In fashion and soft goods manufacturing, effective workforce management is key to meeting customer expectations. Whether your brand operates its own manufacturing facilities or contracts with third-party manufacturers (3PMs), customer relationships are built on keeping a promise to deliver the right products at the right time and the right price.

Most work in a sewing operation is manual, so it's easy to see how labor productivity and performance directly impact product cost, quality and availability. Unfortunately, the majority of fashion and home goods brands lack real-time visibility into their manufacturing operations. Almost all manufacturing facilities track work in progress (WIP) by hand, walking the production floor, counting orders and updating spreadsheets or job boards. Some record WIP using gummed sheets in a production book and transfer the data into a legacy ERP system or an Excel spreadsheet.

Today, with digital transformation on the shop floor, there is a much more efficient way to manage production and your manufacturing workforce by leveraging shop floor control (SFC) software and manufacturing execution system (MES).

Information gathered and recorded manually does not provide the insights you need to make adjustments mid-shift or mid-production order. Instead, a shop floor management system tracks the progress of production throughout your sewing operation; giving supervisors, managers and workers real-time information and notifications regarding WIP, including many aspects of workforce management such as employee productivity, labor costs and pay rates.

Let's delve into 10 benefits of shop floor systems and learn how automation and real-time data can drive more strategic decision-making while increasing overall productivity on your manufacturing floor.

Benefit #1: Increase Production Through Efficient Tracking

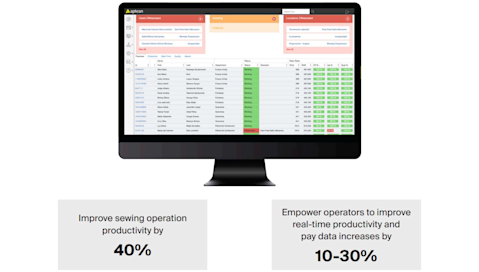

Using a shop floor management solution means that your employees can scan barcodes on pieces or garments rather than writing everything down in a notebook or using gum sheets. This results in an immediate efficiency improvement, along with enhanced decision-making capabilities, enabling sewing operations to experience productivity gains from 11% to more than 40%.*

Extra productivity translates easily into higher profitability. In a large corporation producing 100 million pieces per year, even the minimum 11% productivity gain would result in 11 million extra sewn products to sell each year—without any additional labor required.

*Aptean internal data, based on customers’ real-world results

Benefit #2: Ease Worker Anxiety About Pay Rate Plans

As you'll know, some manufacturers pay operators an hourly base rate plus a piece rate while others pay exclusively by the piece. An industry study of thousands of garment workers around the world discovered that operators with combined hourly/piece pay had more anxiety at work than peers paid solely by a piece rate.* The study’s lead author noted that “workers who are on a combination of pay types are concerned by the variability of their wages and the lack of transparency in how their wages are put together.”

If you're using a combined rate in your operation, you can relieve anxiety about pay by implementing shop floor control software. It gives operators unprecedented pay transparency by displaying updating counts for how many pieces they have sewn and displaying the piece rate, any bonuses and the total pay for the shift.

Once operators develop trust for the system, they no longer spend time making notes about the pay they are owed. Instead, operators watch their garment total increase each time they scan a new piece. Scanning is easier, faster and more accurate than maintaining notebooks full of peeled stickers and hand scrawled notes.

Shop floor management software is a win-win for worker/employer relationships. Stress levels are lower and operators gain time back during every shift that allows them to sew a few more pieces—boosting their own paychecks and your production levels. Empowering operators to be able to see their own real-time productivity and pay data increases efficiency by 10% to 30%, as operators try to beat their own scores and earn more.

*Just-Style, “Piece rate pay a mixed bag for garment workers,” Leonie Barrie, January 4, 2019

Benefit #3: Boost Shop Floor Productivity With Incentive Pay

When considering ways to reduce overall labor costs, paying operators less is not the goal in today’s global political climate with social media ready to amplify the brand damage of any management misstep. Instead, you should endeavor to help operators work more efficiently so they earn more while your company also benefits. Offering extra pay for above-average performance can help speed up the work on important orders, but to make performance pay work, you must have foolproof real-time tracking of operator performance.

Setting up performance pay in a shop floor management system is quick and easy. Payroll or production managers can set rules that adjust the rate for pieces that take longer or require more difficult work to complete. For example, a higher piece rate should be paid for a 3X sized t-shirt than for a small t-shirt.

Real-time data drives incentive pay decisions allowing your company to offer special bonuses on the fly to incentivize a rush order or avoid missing a production deadline. You can also bonus to keep employees on track during times that otherwise exhibit a pattern of lagging production, such as the afternoon before a weekend.

Benefit #4: Reduce Administrative Overhead Costs

Reducing administrative/supervisory overhead through automation can deliver a rich source of labor savings. With shop floor management software, shift supervisors don’t need to walk the floor as much to see everything that’s happening. Nor do managers need to wade through operator notebooks at the end of the day in order to transfer their production information into a computer system.

Imagine a manufacturing operation with 3,000 operators. Let’s assume supervisors work very quickly, spending only one minute per worker each day reviewing the production notebooks and re-entering that data into a pay system. That equates to 50 hours of supervisory work dedicated to this simple task every day. A shop floor control system could do away with this task—saving 18,250 hours per year, or nearly nine full-time employees.

In our manual data tracking scenario, the production and rate information also needed to flow through to payroll processing. Suppose the same 3,000 worker manufacturing operation employed eight payroll professionals. Automation from an SFC system can cut the time required for payroll processing by 60% to 90%, freeing up budget for five or six people to focus on more strategic aspects of workforce management such as hiring and training.

Travel is another expense category that can be cut using shop floor management software. When brands lack visibility into manufacturing operations, product managers are often required to fly around the world to serve as the eyes and ears on the line during production. With a modern SFC, there’s no need for this type of travel because real-time WIP data is available anywhere.

Benefit #5: Enhance Operational Visibility

In order to achieve maximum operational performance, you need maximum visibility. Moreover, visibility is needed at two levels: a high-level, big picture overview across the factory and a drill-down view of real-time production by operator.

Within shop floor systems, management dashboards provide an instant, visual snapshot of key performance indicators (KPIs) for a specific date and time, giving you a great overview of business performance.

Driving higher productivity goals requires sharing visibility into production levels between management and operators. Real-time production screens can display a live feed of units produced and a department line for direct comparison between how many units were made versus target goals. These displays make it much easier for operators and managers to share an understanding of progress towards goals and work together to enhance productivity.

Benefit #6: Pinpoint and Remediate Quality Issues

Shop floor management software provides you with easy-to-view visuals showing all WIP throughout the stages of production, order by order. Supervisors can quickly view KPIs about quality, downtime and other key factors.

Real-time information about defects and repairs helps management identify teams, individuals or production stages where quality suffers, so they can remediate issues and improve quality processes. Incremental quality improvements lead to fewer repairs and reworking and less scrap, supporting business objectives for customer satisfaction and sustainability.

To further ensure quality, SFC tools provide easy access to the information operators need to produce a garment correctly. From their stations or on mobile devices, operators can view instructions, videos or pictures of the products they’re assembling and can notify a supervisor instantly when they need help.

“Even the less tech savvy operators have embraced SFC easily and enjoy using it, which as translated into higher job satisfaction and increased productivity, so much so that Grand Forest achieved a 10% increase in productivity in the first month alone.”

Benefit #7: Plan and Manage Large Orders

When key, larger volume contracts come in from government entities or large retail chains, it’s essential to plan for production. Your management needs to be able to project large orders and plan them further out on the calendar. The plan needs to dedicate key resources such as factories, workers and equipment at the right time to keep production of large orders moving smoothly.

Seasonal planning tools within shop floor management solutions empower you to strategically plan at the corporate level for delivery of critical, large contracts. Easily schedule future projects based on project capacity at specific factories, and also to capitalize on each factory’s specific performance strengths. Planning in advance helps ensure performance on every contract while delivering consistent quality to key customers.

Benefit #8: Minimize Off-Standard Time

When operators are not working their standard jobs, production tends to decline. Many issues can cause an increase in off-standard time, including: power failures, machine delays or breakdowns, meetings, line setting, waiting for additional work and waiting for replenishment of inventory items like trims or accessories. Shop floor management software can automate inventory tracking to ensure that fabric and other items needed during production stay stocked on the line.

You'll also be able to keep track of machine utilization like when a machine becomes inoperable—a belt or a needle breaks, for example— as the system sends an automatic notification to maintenance and supervisors to get the machine up and running more quickly. Some solutions even make predictive alerts to schedule preventative maintenance before machines suffer downtime.

“Due to the integration between Aptean Apparel ERP, Exenta Edition and Aptean Apparel Shop Floor Control, our operators are able to scan their own work. By not having to scan barcodes in the office, we reduced our managerial and administrative time by 80%.”

Benefit #9: Reduce Absenteeism

SFC software systems can help lower absenteeism by giving managers access to complete time and attendance information. Reviewing patterns of absenteeism helps identify employees who do not meet attendance expectations.

Managers can also see if certain stations or lines are overburdened by too few workers or too many temporary workers. This data can reveal areas where cross-training operators may improve coverage of stations when workers are absent.

Benefit #10: Identify Where Additional Training May Be Needed

From a management perspective, shop floor control software makes it easy to identify where efficiency crashes or quality goes down on a production line. If that occurs routinely on a certain product or at one particular station, such as cutting or hemming, it may indicate a need for additional training. It could also indicate that machines are not configured ideally for that station.

Using shop floor management data to drive decision-making in fashion manufacturing helps your executives fine-tune production to meet customer expectations and improve the way the workforce is managed and paid. The software platform provides manufacturers with real-time tracking of both WIP and workforce performance, as well as management dashboards and live production feeds to keep operators and managers informed together.

Using the power of SFC data, you can optimize operator efficiency, offer opportunities to earn incentive bonuses, increase productivity and improve product quality in sewing operations—all while increasing overall profitability.

Introducing Aptean Apparel Shop Floor Control

What happens on your shop floor has a profound effect on many aspects of your organization—productivity, efficiency, quality, customer satisfaction to name a few—and ultimately, directly impacts your bottom line.

But, while critical, optimizing processes is a difficult and complex task. That's why you need an advanced shop floor management system to streamline processes, automate tasks, offer real-time data and boost productivity. And, to get maximum benefit, you'll need a software partner with in-depth knowledge of your industry that will take time to understand your business goals to deliver the best solution.

Enter Aptean. Our industry experience and technical expertise combine to help us deliver innovative solutions tailored to the industries we serve and our relentlessly dedicated teams ensure we're a by-your-side-partner throughout your digital transformation.

To find out more about how our shop floor control software for apparel manufacturers can help your business, check out this blog for the top four reasons fashion and soft goods manufacturers are deploying SFC software.

Or, if you're ready to get started and realize these benefits in your organization, contact us today or schedule a demo.

Related Content

¿Todo listo para transformar tu negocio?

Tenemos las soluciones MES especializadas que necesitas para superar los desafíos de tu sector.