The Pros and Cons of Technology in Manufacturing

The Pros and Cons of Technology in Manufacturing

The Pros and Cons of Technology in Manufacturing

8 Jun 2017

Aptean Staff Writer

Aptean Staff Writer

Technology is something that, no matter how much you may want to, you will now never be able to escape. Every industry and process has been influenced and shaped by the astounding developments made in technology – physical and software – in the last 20 years. No one has been left exempt from this rule, least of all the process of manufacturing and ERP which are increasingly relying on these advances.

Cons:

Disjointed Practice

Sometimes the increased use of technology within the manufacturing process can make things harder rather than easier; more programmes and data to be processed can make the entire process unnecessarily convoluted.

Replication of data

Similarly, more technology can mean replications of data where it isn’t necessary, wasting time and causing confusion.

Breakdowns

If there is a fault in one piece of the tech that is relied on day to day, whether that is on a computer or within a machine, productivity for the day can suffer. The software or hardware being used should work for the end user, not the other way around.

Unseen costs

Further to breakdowns, a high usage of technology can come with a lot of unforeseen costs, and not all are money. Technology, whilst reducing labour costs, can incur further costs to troubleshoot problems. The expertise needed to fix and programme software and hardware would introduce costs that aren’t always predictable. Poorly run projects can also affect the bottom line, creating not only more unseen monetary problems but a negative impact on morale and trust within a company too.

Pros:

Improving the Partner Chain

From the supplier to the end customer, technology can improve the entire supply chain for all those involved in the creation and use of a product. The correct software for the job can tie in all loose ends and ensure that no one step goes undone.

Better Quality

The more advanced technology gets, the more capable and impressive ERPs get. The better an ERP operates, the more efficient and better quality work that is produced through it will be. Picking up on weaknesses in the supply chain and fixing them with a robust ERP solution can revolutionise the way a manufacturer produces a product.

More Consistent

Work within the manufacturing process becomes more consistent and less open to simple human error the more it relies on technology. Technology can accurately forecast, communicate and ensure deadlines are met and that the quality of the work is always the same.

Maximises Throughput

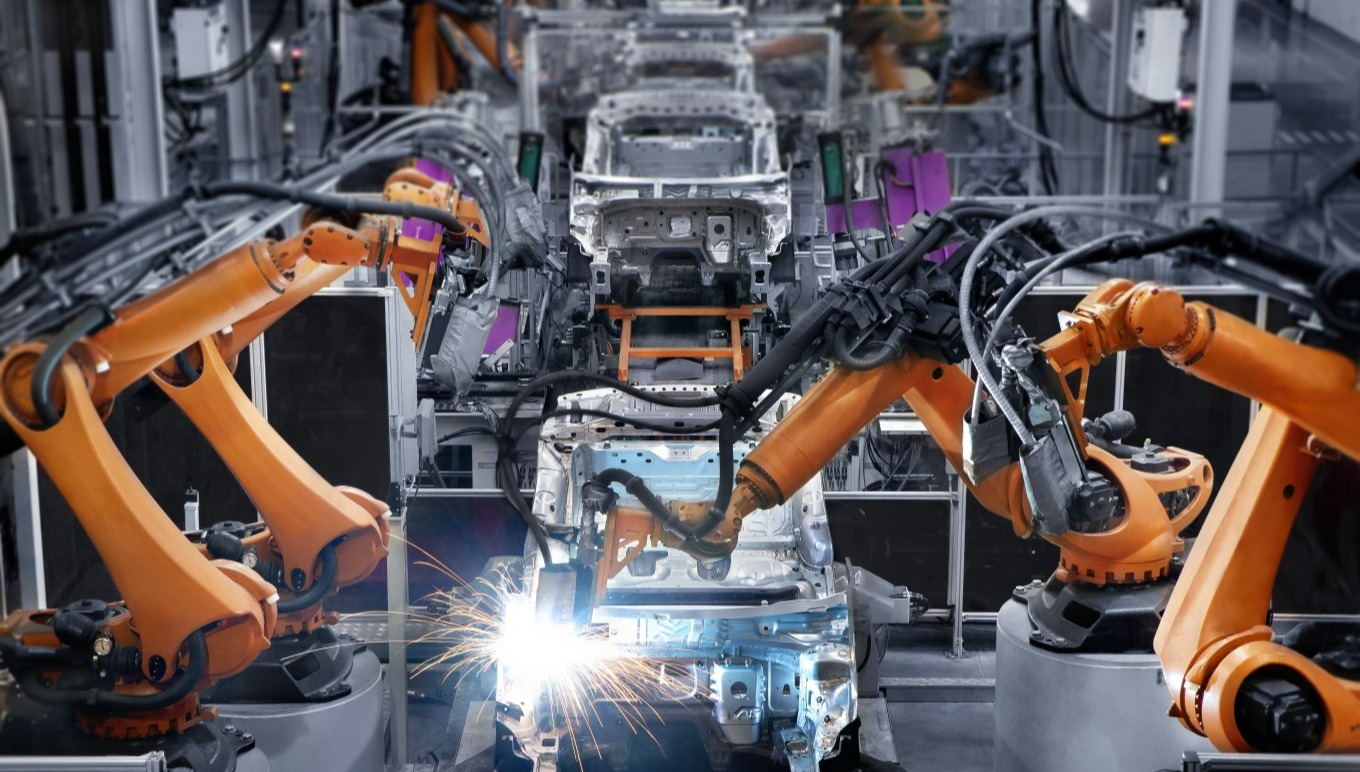

The use of more advanced technology, similarly to the increase in quality, also increases throughput. An advanced ERP system in conjunction with advanced robotics can help better the use of time within the supply chain, making it easier to handle large volumes of work.

Safety Increase

The more technology is being seen within the manufacturing process, the less likely it is that humans will be injured in the working day. Technology can predict risks within the work place and can implement safety measures around this, as well as being able to remove humans from potential harm all together with the use of robotics.

Specific Order Capability

Technology has greatly helped those working in the Engineer to Order and Make to Order sectors. By having software than can facilitate the design and production of materials as well as integrated order tracking capabilities can provide a welcome boost in productivity and time saved for engineer and manufacture-to-order businesses.

Technology can be the cause of many flaws within the manufacturing process but with the right ERP system this should be happening very rarely. Using an intelligent and intuitive platform designed specifically for your industry and needs, especially within the ETO and MTO sector, should increase the amount of pros vs the amount of cons. ETO and MTO have such specific needs that not all ERP systems are suitable or capable of keeping up with the demands.

Start Transforming Your Business Today

If you’re ready to take your industrial manufacturing business to the next level, we’d love to help.