Manage the Impact of Rising Costs With a Specialized ERP for Meat and Seafood Businesses

Manage the Impact of Rising Costs With a Specialized ERP for Meat and Seafood Businesses

Manage the Impact of Rising Costs With a Specialized ERP for Meat and Seafood Businesses

Jul 28, 2023

Aptean Staff Writer

Companies like yours that specialize in the meat, poultry and seafood industries are required to successfully navigate a complex set of challenges to remain successful.

Internally, you need to maximize unique production, labelling and packaging processes whilst you deal with continued pressure to ensure quality assurance, food safety and integrity is maintained across everything you produce.

External influences are however putting additional pressure on these processes and in particular impacting costs and profitability of meat and seafood processors. The economic and geopolitical landscape has been a major contributor, with the global energy crisis having a significant impact on these high energy-intensive sectors. Both heating and cooling food requires large amounts of energy. Cold is needed to chill meat to ensure food safety, and heat is needed for cooking, steaming, simmering, sterilization and cleaning. In addition, there is water consumption for cleaning and disinfecting manufacturing facilities.

Fluctuating prices of raw materials, such as feed and welfare expenses for livestock, and transportation costs on land and sea are also eating into your slim profit margins.

The Soaring Cost for Meat and Seafood Producers

The global food price index averaged an all-time high in March 2022, and inflation remains the highest level of concern for the food and beverage industry, with higher operating costs and the need to raise prices projected to make the largest impact on the industry over the next five years.

Specifically, the meat, poultry and seafood sector saw some of the biggest price increases, and these industries all declined in growth in 2022 compared to 2019 figures. Cod and haddock prices have risen by 50%, and according to recent figures from the ONS, beef and veal has increased by 14.8%, poultry by 18.0% and pork by 25.2%. However, due to low consumer confidence, it is proving difficult to pass these price rises on to the end customer.

This dynamic environment is forcing a constant evolution in operational processes, particularly as you seek new methods for managing fluctuating costs across the supply chain; sourcing high quality, low-cost raw materials; and ensuring pricing accuracy. This requires operational agility, insight and efficiency to maintain profit margins and to continue to be successful.

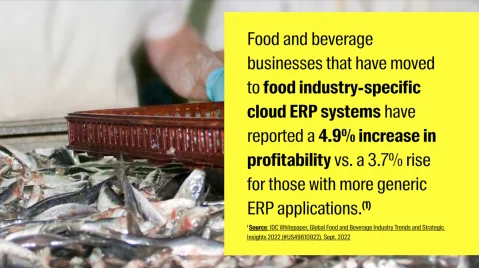

Whilst the reasons for rising costs cannot be controlled by technology, digital transformation and efficiencies gained from automation can help to offset their impact. Furthermore, enterprise resource planning (ERP) systems built to service the unique industry requirements of the meat, poultry and fish sector can deliver even greater improvements to profitability and business resilience.

This blog further examines how a food industry-specific ERP solution for the meat and seafood vertical can help to bolster operational processes and protect profit margins in this volatile economic environment.

Manage Rising Costs and Optimize Profits With Meat and Seafood ERP Functionality

Reducing expenditure without sacrificing quality and output ensures that every financial outlay you make will produce a return. Prospering meat and seafood companies have realized significant cost benefits with ERP systems, particularly where their unique requirements—such as dealing with variable weight products, pricing, perishability and waste reduction—are addressed.

Aptean’s ERP for meat and seafood companies has proven capabilities for cost savings over and above generic ERP solutions.

The perishable nature of meat and seafood means both product and money can be wasted if inventory is not managed efficiently. Inventory management within our seafood and meat ERP solution can help you keep track of the expiration dates and warns users in advance of approaching timelines so that they can be incorporated in production to prevent products becoming outdated and that investment wasted.

Robust production planning tools and the precise alignment of supply and demand help to maintain optimal inventory levels. With the insight that a purpose-built system can provide, you can order and pay for what you need to fulfill customer orders without excess that could spoil.

With demand forecasting, you can also predict seasonality in demand even for specific products—think summer barbeques and turkeys at holidays like Thanksgiving. With reliably accurate projections of consumers’ appetites and the expected sales in any given period, your business can take advantage of seasonal changes and maximize profitability.

Aptean Food & Beverage ERP can help you track more than 500 key performance indicators (KPIs), over 300 of which are specific to the food and beverage world. These inbuilt business intelligence insights provide a greater understanding of which lines are making money, and scenario modeling shows how potential changes would affect your organization’s profitability.

You can use fast order entry functionality to quickly create sales orders with the products you want to promote to specific customers. When a certain product becomes available in your customer item catalogue, you can immediately notify your sales team for quick order processing.

Trade management and advanced pricing help you optimize profit by using hierarchical pricing models and advanced discounting methods to create the best deals with clients.

Lot management tools are traditionally not optimized for the meat/proteins industry in generic ERP systems and accommodating cut and grade labels will require inefficient workarounds. Integrated quality management and related functionality easily allows for the assignment of grades on a lot-level and cuts on an item-level.

Similarly, scale integration may require significant reworking. Our meat and seafood ERP solution can be natively integrated with connected scales to accurately track variable weights across the supply chain.

In terms of labor, mobile warehouse capabilities enable your workers to accomplish critical inventory management tasks with speed and accuracy using handheld barcode scanners. Rather than having to rely on pen and paper for later re-entry in a spreadsheet, employees can simply pull a trigger or push a button to immediately log important information and update the shared database, streamlining their efforts and optimizing resource costs.

All of this functionality in our ERP for meat and seafood businesses can help you streamline processes, improve efficiency and optimize profitability. But, when it comes to the protein processing industry, there is one feature that stands head and shoulders above the rest and is simply not available in generic systems—catch weight management.

Let's dive in to how this key functionality can help bring significant cost reductions to your protein processing operations.

The Importance of Catch Weight in Cost Reduction

Catch weight—the practice of measuring and pricing meat and fish products based on their actual weight rather than an average standard unit of measure—is important for managing costs and profitability.

It is vital for business likes yours that sell products by the unit, case or pallet but price them according to variable weight. This means you can capture the true product value and never leave any margin on the table by always charging end-customers the appropriate amount.

From a purchasing perspective, it also means that you are paying for the exact product weight, ensuring you don’t overpay. Managed well, catch weight also allows for more granular analysis of product profitability, identifying which items deliver the best margins.

You can also gain a clearer understanding of your inventory levels, resulting in better forecasting and reducing the risk of costly overstocking or understocking. Additionally, it can help you identify cost drivers, evaluate supplier contracts and negotiate better terms.

By Not Managing Catch Weight Effectively, the Following Can Occur:

Margin erosion. Manual calculation of catch weights or using the nominal weight of products results in inaccurate final invoicing and a loss of already-slim margins.

Incorrect shipments and miscalculated values. Catch weights need to be tracked on an item-level and be traceable across the entire supply chain.

Decline in customer satisfaction. End-customers now demand a clear understanding of exactly what they’re being billed for and transparency into how the purchase price is calculated. This is key to maintaining loyal and repeat customers.

Product inconsistency. Products that are too small or too large (or too light/heavy) are less desirable; there needs to be a certain level of uniformity, even though weights vary.

Using technology to manage catch weight can help you avoid these issues and accelerate the impact of your cost management strategy. But as catch weight is such a specific process to your sector, generic ERP solutions often do not offer this capability and must be configured as an add-on, potentially through a third party, which can carry additional costs.

Even solutions that can support the meat and seafood processing sub-verticals often have less flexibility around catch weight variability or don’t incorporate the visibility of values at an item-level.

How Aptean’s Catch Weight Capabilities Drive Effective Cost Management

Having discussed the role and value catch weight plays in reducing costs, let’s get a closer look at how the inbuilt capabilities of our seafood and meat ERP can help.

Developed by industry experts, our catch weight functionality is natively integrated into Aptean Food & Beverage ERP out-of-the-box without any costly modifications and directly connected to the financial and accounting capabilities for enhanced reporting and transparency.

Key Benefits of Our Meat and Seafood ERP’s Catch Weight Functionality:

Define catch weight settings on your terms. Dictate how catch weight should be calculated per item and establish either pounds or kilograms for the unit of measurement so each transaction along your supply chain is consistent throughout production. Enable greater flexibility with catch weight by establishing acceptable variability of weight quantity per item or dictate that items must be a specific fixed weight.

Automate catch weight calculations. Our ERP for meat and seafood allows users to define how the catch weight should be calculated for each product and then automatically calculates invoice totals. That allows you to establish consistency all through the supply chain, track both units and weight for each product and remove error-prone manual calculations when invoicing customers so margins are always maintained.

Track catch weight across your entire supply chain. An item weight ledger entry is generated alongside every catch weight item you create. This ensures the weight quantity of your inventory—at item, license plate and lot number level—is tracked at every step in your supply chain. In addition, weight lines are created and linked to this item tracking lines to increase visibility of the weight quantity to handle, weight quantity handled, weight quantity to invoice and weight quantity invoiced for each shipment. By creating parameters for acceptable weight thresholds, you can then be responsive to any unacceptable weight variances as they occur and ensure they do not proceed down the supply chain.

Give your customers full transparency into weights. Directly transpose exact weight values onto documents like sales invoices, individual item labels and wherever better visibility is needed. Once you reach the actual invoice process, you’re able to accurately charge customers based on the shipped weight quantity with full documentation of weight values per item.

These industry-specific features allow meat, poultry and seafood producers to seamlessly digitize their operations ready for growth and save on costs in the long term.

Ready to Tackle Soaring Industry Costs With Aptean?

Like many food and beverage sectors, the meat and seafood industry is facing the tough reality of rising customer expectations and soaring costs. Balancing the two is no mean feat, but doing so successfully is what will help you stand out from the crowd, increase profitability and future-proof your business.

That's why you need advanced industry-specific software in your corner, from a partner that "speaks your language" and can hep guide you through all the steps of your digital transformation. Enter Aptean.

You've already heard how our specialized meat and seafood ERP can help your business meet the challenges of your industry, but the benefits don't stop there. From our overall equipment effectiveness (OEE) software to our route optimization system, we offer a full software suite to help you reduce costs and power your growth. All of our systems are backed by our dedicated in-house teams that know your industry inside-out, and many of our solutions are offered in the cloud for enhanced security, scalability and accessibility.

Ready to find out how our specialized ERP functionality, like catch weight management, can help you face the market fluctuations and unique challenges of the meat and seafood industries? Contact us today, or request a specialized demo.

Related Content

Ready for purpose-built solutions to streamline protein processing operations?

Our ERP for meat and seafood processors drives positive change and acts as a future-proof platform for growth.